How Fixed Gas Detectors Are Revolutionizing Safety Protocols in Various Industries

2025-08-11

How Fixed Gas Detectors Are Revolutionizing Safety Protocols in Various Industries

In today's rapidly evolving industrial landscape, safety remains a paramount concern. Among the most significant advancements in this arena is the deployment of **fixed gas detectors**. These devices are not merely tools; they are pivotal instruments that are reshaping safety protocols across various sectors. This article delves into the transformative characteristics of fixed gas detectors, their applications, benefits, and the future of gas detection technology.

Table of Contents

- Understanding Fixed Gas Detectors

- Importance of Gas Detection in Industries

- How Fixed Gas Detectors Work

- Types of Fixed Gas Detectors

- Benefits of Fixed Gas Detectors

- Installation and Maintenance

- Case Studies and Real-World Applications

- Future of Gas Detection Technology

- FAQs

- Conclusion

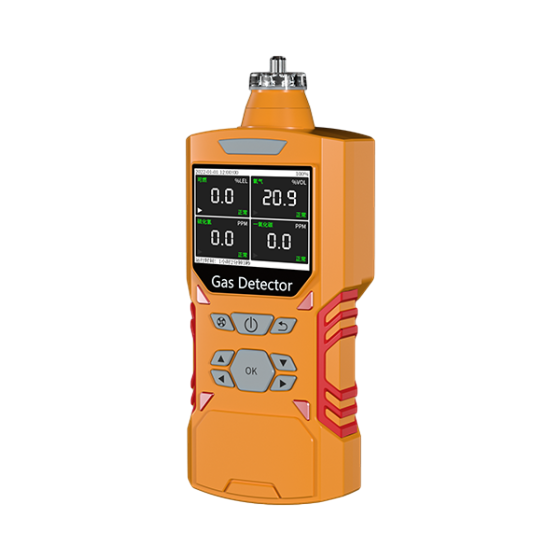

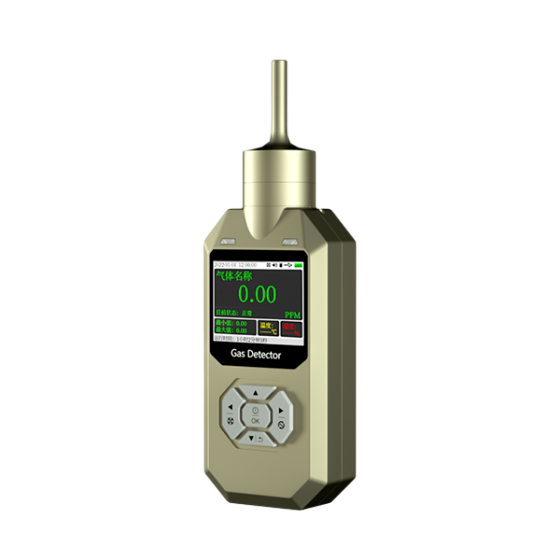

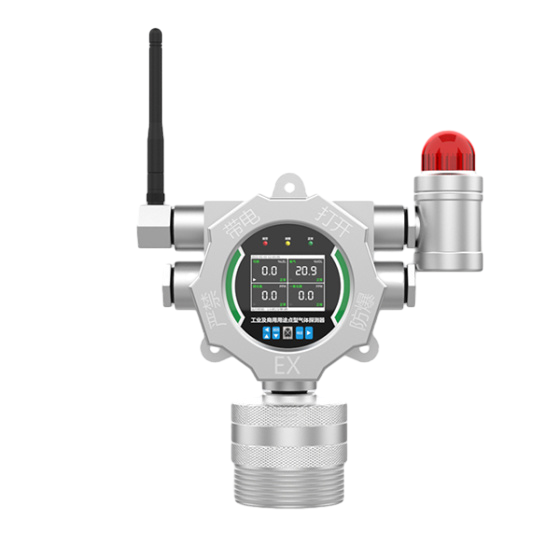

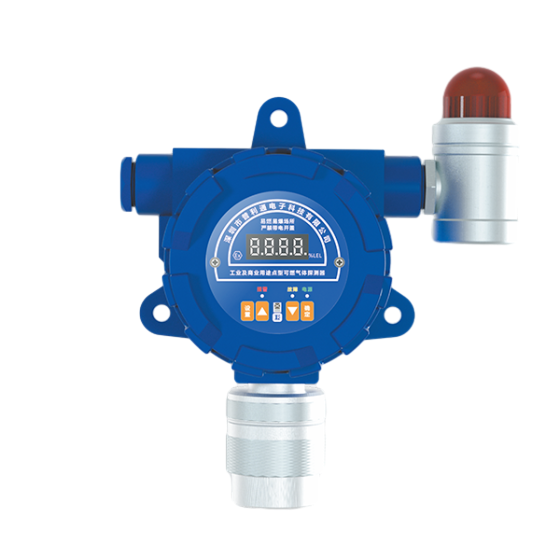

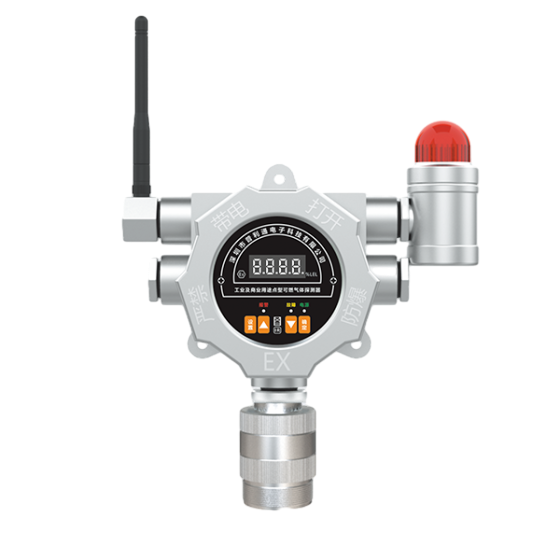

Understanding Fixed Gas Detectors

Fixed gas detectors are advanced devices designed to continuously monitor the concentration of gases in a specific environment. Unlike portable gas detectors, which can be carried around, fixed detectors are permanently installed in designated areas, providing constant surveillance for harmful gases. These devices are equipped with sophisticated sensors that detect various gas types, including toxic and flammable gases, ensuring that potential hazards are identified promptly.

Key Components of Fixed Gas Detectors

Understanding the components of fixed gas detectors is essential to appreciate their functionality. Key components include:

- Sensors: The heart of the detector, these can be catalytic, electrochemical, infrared, or semiconductor types, each tailored to detect specific gases.

- Transmitter: This component converts the sensor's readings into a signal that can be communicated to a control panel or monitoring system.

- Alarm System: Fixed gas detectors are typically equipped with visual and audible alarms to alert personnel of hazardous gas levels.

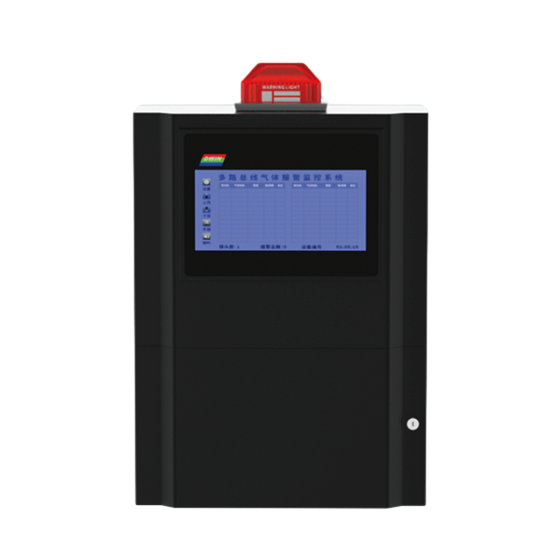

- Control Panel: This is where all data is aggregated, allowing for real-time monitoring and control of gas levels across the facility.

Importance of Gas Detection in Industries

Gas detection is crucial in various industries, including manufacturing, oil and gas, chemical processing, and mining. These sectors often deal with hazardous materials and gases, making effective gas monitoring indispensable for protecting workers, the environment, and company assets.

Preventing Workplace Accidents

Fixed gas detectors play a vital role in preventing workplace accidents by providing early warning systems that help avoid catastrophic events such as explosions and toxic exposures. By ensuring that gas levels are monitored continuously, companies can react swiftly to any dangerous situations.

Regulatory Compliance

Many industries are subject to stringent regulations regarding air quality and worker safety. Implementing fixed gas detectors not only ensures compliance with these regulations but also enhances a company’s reputation as a safety-conscious organization, potentially reducing insurance costs and liability risks.

How Fixed Gas Detectors Work

Fixed gas detectors operate through a series of steps designed to ensure accurate monitoring of gas levels. Understanding this process helps underscore their importance in safety protocols.

Detection Mechanisms

Fixed gas detectors utilize different detection mechanisms, depending on the gas type being monitored. For example:

- Infrared Sensors: These sensors measure gas concentration by analyzing light absorption at specific wavelengths.

- Electrochemical Sensors: These sensors use chemical reactions to detect gas presence, often employed for toxic gases.

- Catalytic Sensors: These sensors are typically used for flammable gases and work by oxidizing the gas, producing heat that is measured to determine concentration.

Data Transmission and Analysis

Once gases are detected, the information is transmitted to the control panel, where it is analyzed and displayed. In case of abnormal readings, the system triggers alarms and notifies personnel, enabling immediate action to mitigate risks.

Types of Fixed Gas Detectors

There are various types of fixed gas detectors, each designed for specific applications and types of gases.

Single-Gas Detectors

These detectors are specifically tailored to monitor one type of gas, making them useful in environments where only one hazardous gas is present.

Multi-Gas Detectors

Multi-gas detectors can monitor several gases simultaneously, making them ideal for complex industrial environments where multiple gases may be present.

Combination Detectors

These devices integrate multiple detection technologies (such as electrochemical and infrared) within a single unit, allowing for a broader range of gas detection capabilities.

Benefits of Fixed Gas Detectors

The implementation of fixed gas detectors offers numerous benefits, significantly enhancing workplace safety.

Enhanced Safety Measures

By providing continuous monitoring, fixed gas detectors enhance safety measures, allowing for real-time alerts in case of gas leaks or hazardous levels. This proactive approach prevents accidents before they occur.

Cost-Effective Solutions

While the initial investment in fixed gas detectors may be significant, the long-term savings associated with reduced accidents, regulatory fines, and insurance premiums often outweigh the costs.

Improved Operational Efficiency

Fixed gas detectors contribute to improved operational efficiency by minimizing downtime caused by accidents or compliance issues, thereby ensuring smoother business operations.

Installation and Maintenance

The effectiveness of fixed gas detectors largely depends on proper installation and regular maintenance. Following industry best practices is crucial for optimal performance.

Installation Best Practices

When installing fixed gas detectors, considerations include:

- Location: Position detectors strategically in areas prone to gas accumulation.

- Calibration: Ensure each detector is calibrated according to the manufacturer’s specifications for accurate readings.

Routine Maintenance

Regular maintenance is essential for ensuring detectors remain functional over time. Routine checks should include testing the sensors, replacing batteries, and ensuring that alarms are operational.

Case Studies and Real-World Applications

Fixed gas detectors have been successfully deployed in various industries, demonstrating their effectiveness in ensuring safety.

Oil and Gas Industry

In the oil and gas sector, fixed gas detectors are essential for monitoring hazardous gases like methane. Their implementation has significantly reduced the risk of explosions and emissions, enhancing both worker safety and environmental protection.

Chemical Manufacturing

In chemical plants, fixed gas detectors monitor toxic gases, ensuring that safety protocols are adhered to and minimizing the risk of exposure. This has led to safer work environments and compliance with stringent regulations.

Future of Gas Detection Technology

The future of gas detection technology is promising, with innovation driving new developments in detection accuracy and efficiency.

Integration with IoT and AI

The incorporation of Internet of Things (IoT) technology and Artificial Intelligence (AI) is on the horizon. These advancements will lead to smarter fixed gas detectors capable of predictive analytics and automated responses, significantly enhancing safety measures.

Enhanced Sensor Technologies

Future developments may include more sensitive sensors capable of detecting lower gas concentrations, thus improving early warning systems and response times.

FAQs

What are fixed gas detectors?

Fixed gas detectors are installed instruments designed to continuously monitor the presence of hazardous gases in a specific location.

How do fixed gas detectors work?

They work by utilizing sensors to detect gas concentrations and relay that information to a control panel, triggering alarms when dangerous levels are reached.

What types of gases can fixed gas detectors monitor?

Fixed gas detectors can monitor various gases, including toxic, flammable, and asphyxiating gases, depending on the type of sensor used.

How often should fixed gas detectors be calibrated?

Calibration frequency may vary by manufacturer, but generally, detectors should be calibrated at least annually or according to specific industry standards.

What are the benefits of using fixed gas detectors?

They improve safety, ensure regulatory compliance, reduce operational costs, and enhance overall workplace efficiency.

Conclusion

Fixed gas detectors are revolutionizing safety protocols across various industries by providing continuous monitoring and early detection of hazardous gases. Their significance in preventing workplace accidents, ensuring regulatory compliance, and enhancing operational efficiency cannot be overstated. As technology advances, the future of gas detection looks promising, with innovations that will further elevate safety standards. Investing in fixed gas detectors is not only a smart business decision but also a critical step towards a safer work environment for all. We encourage industries to embrace this technology and prioritize safety as an integral component of their operations.

Related Info

Combustible gas alarm maintenance

2020-07-03

2021-01-14